Internship Testimonial: KOMUT Studio

My name is Marianne Proops, and I am an SDM alumni student. After completing my thesis project, which was focused on design and sustainability, I decided to pursue my interest in alternative design practices and secured an internship at KOMUT Studio (https://komut.studio/).

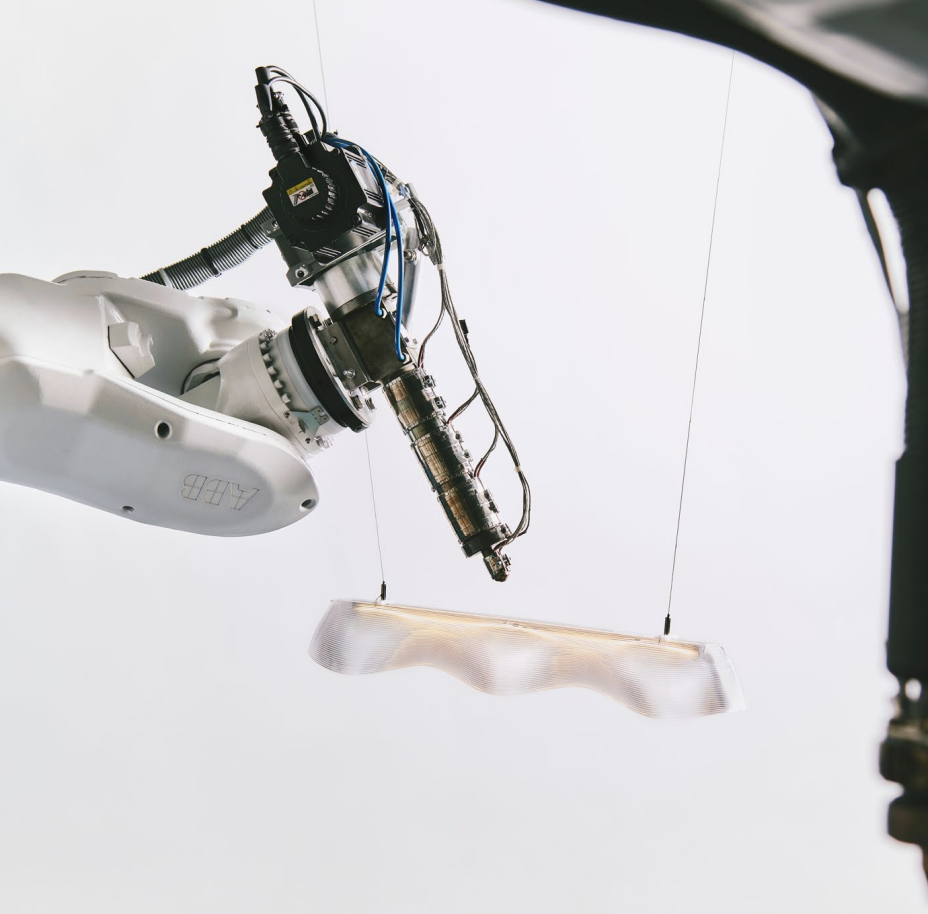

KOMUT Studio is a design studio based in Paris with the mission to be 100% carbon neutral, creating circular furniture and lighting—Made in France.

I began my internship in November after a few rounds of interviews. From the very first day, it was an instant match with my values. I started diving into the world of 3D printing and sustainable design, working with an innovative team dedicated to creating indoor and outdoor furniture with a positive environmental impact.

The team is composed of creative individuals who are experts in their fields and deeply care about their environmental impact. They also prioritize sharing their knowledge and making me feel like part of the team. I felt included from the very beginning. While hard skills, such as proficiency in specific software, are important throughout the design process, communication and trust are even more critical when creating products as a team. My team needs to trust me as we all work on different tasks, and they give me the autonomy to manage my own time to ensure that all missions are completed. Communication is also key. I work with powerful machines, and for my safety, I must communicate with my team if anything goes wrong. Overall, I feel very valued both as a member of the team and as an independent creative.

Through my internship, I was introduced to design concepts, production plans, and an engineering approach to design. My skills in 3D design provided a solid foundation, but first, I needed to understand the company’s processes. Internships are opportunities to

learn on the field, so listening and observing have been an important part of my role. One skill that was especially useful from the beginning was my attention to detail. Rigour is not only for the validation of others but also for my own satisfaction. For instance, when I’m in charge of producing a 2-meter-long panel, I must be meticulous for my own safety and avoid having to redo the panel multiple times. As my mentor often says, “With 3D printing, you cannot control all the parameters, so the only thing you can control is yourself.”

3D printing on such a large scale is fascinating. Some prints can take up to 10 hours, and during that time, it requires constant focus to ensure nothing goes wrong. Imagine spending 10 hours on a print only to have it warp in the last 30 minutes. I’ve even started paying more attention to weather forecasts, as factors like temperature and humidity can significantly impact prints. The production process demands focus and quick action in case something goes wrong. Some might even say I’ve developed “ninja skills.”

In conclusion, this internship is an invaluable learning experience. It has not only allowed me to deepen my knowledge in sustainable design and 3D printing but also reinforced the importance of teamwork, communication, and personal discipline in the creative process.